Technology Overview

Employing a pulse filter rectifier equipped with a turbocharger: After five years of relentless efforts by the engineering team, a step-by-step ionization of special mixed gases has been developed. This expands their energy to form a high-energy ion body, transforming the substance into a nearly neutral gas composed of positively charged atomic nuclei and negatively charged electrons. This is then stimulated by a plasma processor into a high-velocity arc spray. As the arc ultraviolet machine turbocharges the gas up to high rpm, inert gases and mixed gases can be fully ionized, a process that relies on both chemical and physical methods. This technique can be applied to optimize the surfaces of various materials.

How it operates

Initiating the operation of the arc cyclotron, the material becomes an electrically neutral gas. The conductivity of this gas and its electromagnetic field have a strong coupling effect on the surface. The arc spray gun emits flames similar to those of a fighter jet's afterburner. Utilizing high-speed rotation, the arc's electromagnetic field produces extremely fine friction with the surface, reducing it to near-nanoscale and thereby optimizing the surface.

Durable Surface Modification

The durability of surface treatment on various materials in general market applications varies. The duration before the treatment becomes ineffective depends on factors such as material properties and storage time, which can be quantified using a dyne pen and a contact angle measuring instrument. Tests have been conducted on different materials numerous times.

After years of research and development in collaboration with optical scientists, a special mixed gas has been discovered that can be applied to multiple material surfaces and provide a lasting modification, preventing the treatment from becoming ineffective over time.

Enhancing Results When Applied to Various Materials

Enhancing Results When Applied to Various Materials

- To adapt to varying densities and hardness of different materials, the Plasma Arc Ultraviolet machine can be used to modify the product surface.

- It can optimize the surfaces of TR-90, nylon, PC plastic products, stainless steel metal products, titanium alloy metals, acetate fibers, and various composite materials.

- During procedures such as baking paint, PVD, electroplating, anodic plating, and color painting, it can effectively enhance color adhesion.

The Plasma Arc Ultraviolet Machine Helps Remove Fuzz from Medical Equipment

- The UV laser source drives the laser light to stimulate gas, which then vaporizes into micron particles.

- The high-speed cyclone gun head makes the gas and product objects generate high-speed rotating friction.

- By continuously releasing plasma ions, the machine can discharge and remove tiny burrs at the tip.

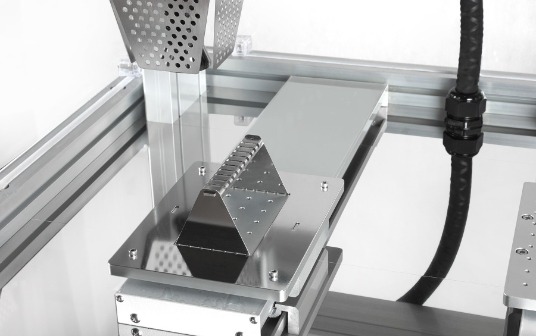

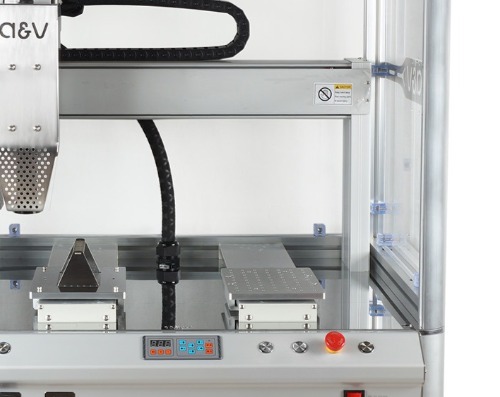

Machine Photos