What We Offer

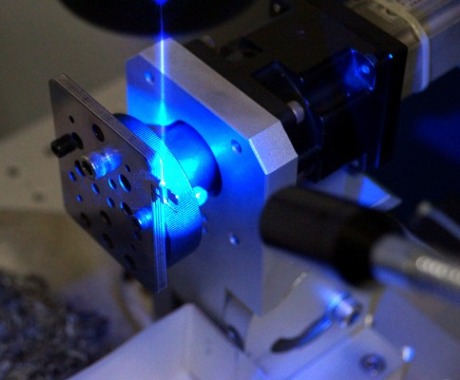

Laser Welding

Laser welding uses a high-energy-density laser as a heat source to irradiate the junction of metal workpieces. The two separate pieces absorb energy, quickly melt, and form a molten pool. After cooling and solidifying, they are physically connected together. Precision laser welding paths range from 0.1mm to 0.5mm, which is suitable for small-batch production and development testing. When welding metal workpieces such as stainless steel sheets, iron sheets, and galvanized steel sheets, the weld is fine, the speed is fast, and the deformation is small, perfectly replacing traditional argon arc welding and electric welding processes.

Best Service

We have been engaged in precision metal laser cutting for many years, with many years of professional technology and experience. To provide you with the best service.

Process Integration

After discussions between senior designers and customers, integrate metal or composite material technology to create success together.

Quick Reply

With a professional design team and production team, discuss and confirm through the customer's drawings, and reply within three working days at the earliest.